There is a growing movement in the construction industry to adopt LEAN principles to streamline jobsite labor productivity. As one of the primary costs of construction, labor alone constitutes as much as 30% of overall project cost, and represents the cost that is most subject to uncertainty and risk. This risk is predominantly due to compromised site productivity on projects where there’s a high degree of wasteful, non productive labor time.

In fact, it’s common to view labor productivity as the sole determining factor of overall project performance and profitability – i.e. project success or failure is directly dependant on labor productivity. Other primary project costs – such as procurement, equipment, materials and engineering – can have associated risk and uncertainty but are marginal in comparison to risk associated to labor productivity.

Non-Productive Time at the Jobsite

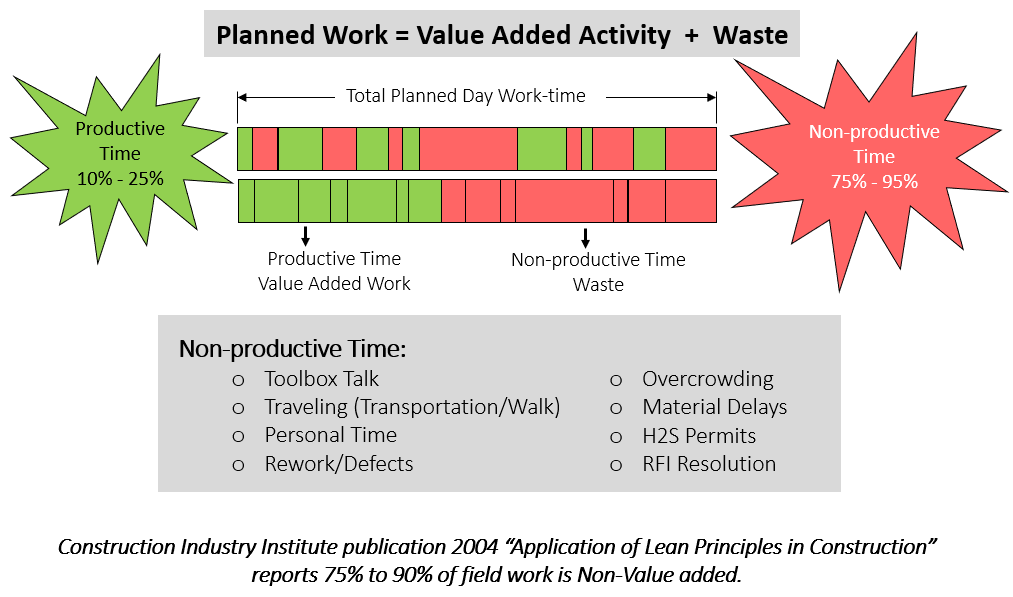

Non-productive time is simply defined as any time spent not actually performing job-related activities. This can include:

- Toolbox Talk

- Travel time – walking or transporting from one location to another

- Personal time – coffee, cigarette, washroom, other

- Addressing Rework/Defects

- Conflicts between trades

- Wasteful activities such as waiting on materials or other dependencies

- H2S Permits

- RFI Resolution

- Other non-value-added work

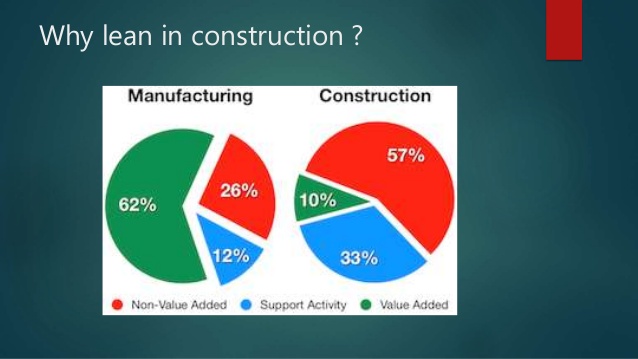

Each of these non-productive activities can eat up a significant chunk of all your jobsite personnel. According to key findings made by the Construction Industry Institute paper Lean Principles in Construction, “Only ten percent of field construction activities add value.” The rest is considered waste or non-productive.

What is Lean Construction?

Lean construction borrows its elimination-of-waste concepts from Lean Manufacturing, where the idea of Lean has been a common practice for decades. The goal of Lean is defined as, “The continuous process of eliminating waste.” In manufacturing, where margins are thin and productivity is critical for success, non-productive and wasteful activities are significantly reduced, and labor productivity factors are much higher than in construction. Compare the 10%-25% of productive work in construction to the 60%-75% productive work in manufacturing (https://www.leanproduction.com/).

Studies suggest that the adoption of Lean Construction can save up to 30% of the project cost. Moreover, if a contractor were to adopt even a few lean concepts, they could improve their value-add activities up to 20% and would wield a significant competitive advantage over other contractors.

Of course, it’s impossible to eliminate all non-productive, wasteful activities, however what can be done, is reduce the size and impact of waste. What Lean suggests, is to first identify wasteful activities, and spend more upfront planning time on how to reduce it. For example, if more upfront time were spent looking the layout of the jobsite, crews would spend less time walking back and forth to the lunch trailer, or to the washroom. Something so simple as streamlining the movement of people within the jobsite can have an instant financial and productivity reward.

If you’ve never seen the movie “The Founder”, it’s a simple but excellent example of how the success of the McDonald’s food chain was significantly impacted by their goal of making fast food delivery efficient and accurate. They invest a tremendous amount of effort in designing the restaurant kitchen to maximize efficiency, eliminate collisions, and make sure they get the orders right.

Demand Better

To account for labor productivity issues, owners and contractors in construction will typically add productivity contingency in their estimating rather than directly addressing the issue. While this is common practice and generally accepted, it’s far from a resolution and a clear sign that something is intrinsically broken. Whether you’re an owner or contractor, it may be time to

Careful Project Cost and Hour Tracking

The first step in tackling labor productivity issues, is to move forward on implementing a cost tracking system so that you can begin gathering metrics on where hours are being spent, along with getting a good handle on productive versus non-productive time. Once you’re tracking your labor productivity effectively, you’ll then be equipped to implement better measures for eliminating wasteful, non-value-add work.

Platform

Platform Solutions

Solutions Owners

Owners Contractors

Contractors Engineering/EPCM

Engineering/EPCM Professional Services

Professional Services Resources

Resources White Papers

White Papers Case Studies

Case Studies Blog

Blog Videos

Videos Frequently Asked Questions

Frequently Asked Questions Company

Company About

About