Read In 7 Minutes

Unit Price contracts are a common way for owners to define the structure of how a project is quoted and delivered by contractors. Unlike Fixed Price (lump sum), unit price contracts are an agreed-upon price per unit installed, completed or delivered. Some refer to this contract type as a BOQ (bill of quantities), Schedule of Values, or Re-measurement project. In any case, it boils down to an established price a contractor will charge for the completion of a quantifiable deliverable.

Bill of Quantities

Part of the owner’s motivation is to compare rates from the different quotes tendered. Using this technique, there is an undetermined project size and still compare vendor bids. With unit-price projects, the owner provides a Bill of quantities (BOQ, or schedule of values) which the contractor quotes against on a price-per-unit basis. A BOQ item is an item of work that is stated and measured based on some unit amount; where a “Unit” could be, for example, “feet of pipeline” or “cubic yards of dirt” moved. An example of a BOQ item could be, “Install 8,750 feet of pipeline”.

An entire project is made up of many of these BOQ items, each with its own units and quantities. The owner is primarily interested in seeing the price-per-unit for each BOQ item, along with the total project tallied up for a complete quote. As mentioned above, the quantities of the work at a tender stage are approximate. The actual volumes are measured and paid as the work proceeds and deliverables are completed.

Next Steps

This way of quoting, measuring, and operating a project is fair to both owner and contractor because both absorb an equal amount of risk. As long as the contractor identifies their costs per unit, they can make a reasonable profit if costs are controlled. From the owner’s side, it is easier to manage any uncertainty concerning the final quantities at project completion. This results in forecasting different outcomes based on known costs per unit regardless of the risk of quantities exceeding initial estimates.

Invoicing the client is also simplified since it is based on agreed-to units of progress completed by the contractor. The definition of substantial completion needs to be well documented, and an independent quantity inspector must certify the completed amounts. This results in a small chance for questions or misunderstandings when it’s time to invoice.

Breaking Down Costs

The key for the contractor is to accurately estimate costs per unit for each item in the BOQ. Once they can figure out costs, they can then apply a markup to determine the quoted price per unit. They will often start with the price-per-unit, rather than cost, and work backward to build up their costs, as price can be somewhat predetermined. Once the project is underway, it becomes critical for the contractor to be able to accurately capture their costs; and report those costs on a per-unit basis so that they know if they’re making a profit. They additionally need to drill down on cost details to a more granular, resource level so that they can unveil where the best profits (or losses) are incurred.

For example, an excavating contractor may estimate that they can excavate and haul an area for $129 per cubic yard (cost). But, it’s important to break that cost down into the labor, equipment, material, and expenses required to complete each unit. By estimating at that level, they can then compare budgeted costs against actual costs (and hours) to understand their productivity metrics. If things aren’t working out as planned, they can take corrective action.

Productivity Metrics

Productivity metrics can help you analyze how well your crews are performing. It is a critical part of successfully managing unit price projects once they’re underway. For example:

- Cost per unit. The price-per-unit is fixed according to the contract but collecting the data to calculate the cost per unit requires detailed project tracking.

- Labor hours per unit. Similar to cost, calculating actual hours-per-unit is also a key indicator of performance, and it is important to know if you’re burning more hours than planned.

- Units per day. Unit price contracts often have a baked-in expectation of productivity that’s based on crew performance. Comparing budgeted units per day against actual units per day can be a key metric to know early on if you are falling behind.

- Productivity Index. The productivity index compares estimated versus actual unit productivity and reports it as a value greater than or less than 1. Where less than 1 means underperforming, and greater than 1 is overperforming compared to plan.

Project Tracking

Tracking unit projects is a combination of tracking all field costs, hours, and expenses. This is typical of any construction project, with the added requirement of tracking physical progress by unit increments. Revenue is then recognized by the number of units completed or installed at the predetermined unit price rate. While it is tempting to only track the units, it’s also critical to keep a close eye on costs to determine profitability and productivity. This separation of cost and revenue recognition is a key part of the management of unit price projects.

Learn More About Project Tracking

Change Orders

During a project’s duration, the likelihood to re-measure the estimated remaining quantities for each BOQ item is high. Commonly, the updated count will vary from the original estimate, and the new project size will be determined. From the contractor’s point of view, this is effectively a change order, and an opportunity to re-evaluate the unit price for each item. It’s critical to monitor costs so that you have a solid handle on whether your baseline unit price is accurate. It’s also key to have a baseline so that each re-measurement point can be compared along the way. And if you modify your unit price in the change orders that coincide with the re-measurement points, you’ll have visibility into how the project is playing out.

Learn More About Change Order Management

Contract Expectations

To monitor “Plan versus Actual”, many think of costs or hours in terms of comparing what is budgeted against what has been burned. This is also true of measurable units of completion or progress. The client has an expectation written directly into the contract as to how many units are to be completed on a daily or weekly basis. To fall behind on this schedule can significantly impact the client’s ability to deliver the project.

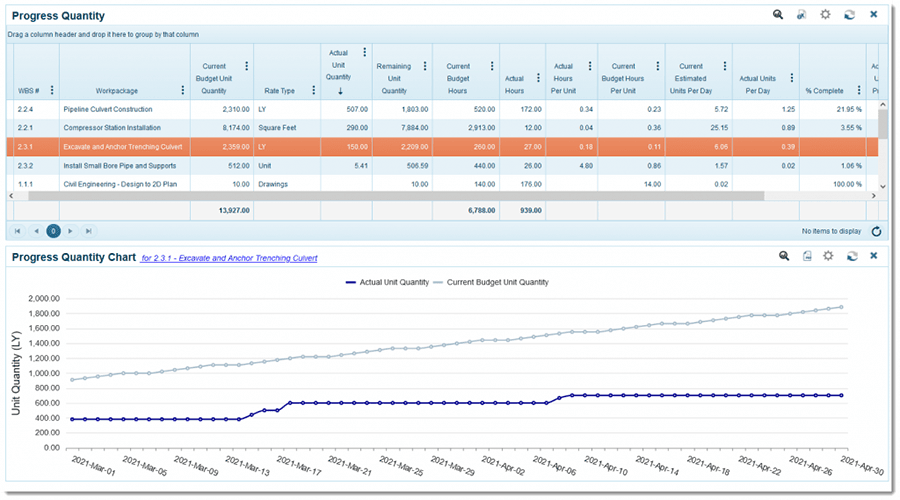

The sample chart from 4castplus demonstrates a standard report that compares planned units over time against actual units completed over time. The top report also shows a selection of productivity metrics. This provides project management with ongoing insight into the success of a unit price project.

Learn More

Maintain tight visibility and control on the costs, activities and productivity of all your subcontractors and suppliers. Materials management, equipment rentals, miscellaneous purchases and subcontracted services can all coexist together with full control over budget, accruals, project inventory and much more. There is no other software system on the market that provides such comprehensive procurement management for construction projects.

Platform

Platform Solutions

Solutions Owners

Owners Contractors

Contractors Engineering/EPCM

Engineering/EPCM Professional Services

Professional Services Resources

Resources White Papers

White Papers Case Studies

Case Studies Blog

Blog Videos

Videos Frequently Asked Questions

Frequently Asked Questions Company

Company About

About