Read In 12 Minutes

Choosing The Right Project Controls Software

Project controls practices have become an essential must-have for teams that need to maintain budget discipline, meet critical deadlines, and ensure they can deliver projects successfully. In the past, one of the main reasons companies hesitated in adopting project controls is that it’s harder to set up and model in spreadsheets, since project controls is data-intensive and relies on numerous financial formulas. This would often push companies into adopting a project controls software platform, which became a barrier as the perception was that project controls systems were difficult, expensive, and required a lengthy implementation. Fortunately, this is no longer the case as modern project controls solutions are much easier to use, affordable, and have a modest implementation timeline.

In the project controls software market, there are a growing number of options available. However, not all systems are alike, and many don’t have the depth in capability required for industrial projects. It’s up to the buyer, therefore, to determine which is the best fit for your business.

To make the choice easier, we’ve highlighted 10 must-have features that any effective construction project controls software should include. These capabilities represent the foundation of what your team needs in order to succeed in an increasingly complex and competitive environment.

- Project planning, cost codes and resourcing

- Time-phased budgeting – cash flow planning

- Progress Measurements

- Earned value management

- Change order management

1. Project Planning, Coding & Resource Management

Every successful project begins with a good plan. It serves as the fundamental structure for representing the project work, deliverables, coding, budget, and resources required to complete the project. To support a solid project plan, the system needs to have, at a minimum, the following planning elements:

- Work breakdown structure (WBS) – A hierarchical representation of the work and deliverables that need to be completed, along with the associated scheduling details.

- Cost breakdown structure (CBS) – A hierarchical representation of the cost codes that hold budget, actuals, progress, hours, etc. The CBS and WBS can be aligned. The project CBS should be able to be unique for each project and not necessarily dependent on the code of accounts in the ERP. The software should, however, be able to map the project codes to the ERP code of accounts.

- Initial budget or estimate – A breakdown of the planned costs broken out by the many types of project costs, such as hours, materials, subcontracts, equipment, etc.

- Resourcing plan – A plan for the labor resources that will be assigned to work on the project. This can include field staff, office staff, finance, etc., along with any required equipment if applicable.

- The project controls system should be able to either create the above planning elements or import (or sync) them from other tools such as scheduling (i.e., P6) and estimating systems.

2. Time-Phased Budgeting | Cash Flow Planning

One of the core essentials of project controls is the ability to merge cost and time. If you have a $100 million project, it’s crucial to be able to forecast how and when that budget will be spent. This is typically referred to as a “Time-Phased Budget” or a cash flow plan. The importance of this can’t be understated because it allows you to understand at any point in time what you planned to have spent by that point and at that point. Without it, there is no feasible way to compare planned versus actual in terms of cost, hours, revenue, productivity, etc.

A time-phased budget starts simply by taking the scheduled start and end date for an activity and evenly prorating the activity’s budget over that timeframe. When this is done for all WBS activities, the result is a timeline of estimated daily spend for the project. This is clearly overly simplistic, so what your project controls system should provide are additional tools to build a cash flow plan for each activity that is more reflective of its spending forecast. Some activities might be front-loaded or rear-loaded, bell-curved, etc. This results in a much more accurate reflection of the project’s cash flow.

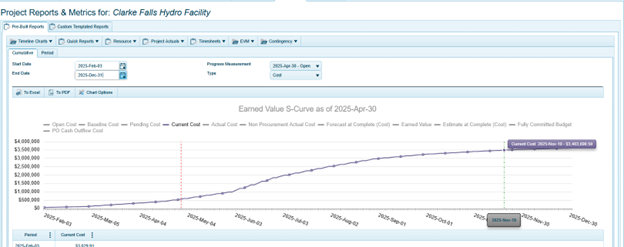

The 4castplus screenshot below shows the budget line of a timeline report (S-Curve) of a project. I’m hovering my mouse over November 19 and the system indicates that by that point in the project the anticipated spend will be just under $3.5M. That number is referred to as Planned Value (PV) and is the key metric we’re looking for in time-phasing.

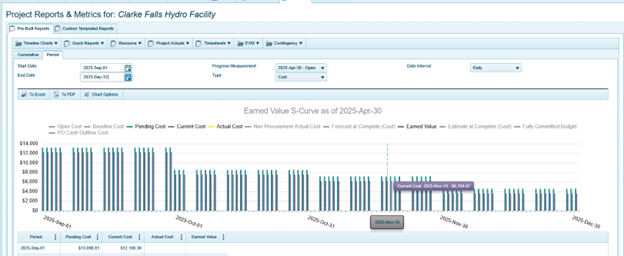

This second 4castplus screenshot shows the same data but in Period view rather than Cumulative view. Again, I’m hovering my mouse over November 18th; however, in this case the system is showing the expected spend on that date.

With a time-phased budget, the project controls team can compare planned value with actual cost at any given time to give a true representation of how budget compares against actual cost. As we’ll see, this can also be measured against Earned Value to get a holistic picture of project performance.

Learn More About Budgeting & Forecasting

3. Progress Measurements

Measuring project progress is intended to objectively answer the question, “How far along are we? I mean, really?”

But that can be a really tricky thing to figure out in larger industrial-level projects. You really want to avoid a subjective guesses, “We’re like 75% done” with no evidence. Or, “We’ve spent 60% of the budget, so we must be 60% complete.” You need to apply an evidence-backed methodology for each activity to measure its progress. Not all activities on a project can be measured in the same way, of course, so each can have its own progress method to measure with. Some you can measure using deliverables-based units completed as the indicator of progress. Such as, items installed, drawings completed, cubic meters of earth moved, inspection completions, length of pipe laid, etc. Other progress methods can be schedule based, or hours based, and others may use the progress of subcontractors. A project controls system should provide a selection of progress methods to choose from that fit the nature of each activity. At minimum, look for the following progress methods available in the system:

- Units completed

- Earned as planned

- Rules of credit

- Weighted steps

- Value of work done (VOWD)

- 0/100 or 50/50 Schedule based

- Percent budget spent

Incremental Progress

The project controls system should also be able to measure progress in iterative cycles. On longer projects, it’s important to take snapshots at incremental points in time – similar to a period close in an accounting system.

Learn More About Progress Measurements

4. Earned Value Management (EVM)

Earned Value Management (EVM) is the gold standard for measuring project health. Software with robust EVM capabilities gives you a single integrated view of cost performance. Your project controls system should provide EVM planning, tracking, and analysis out of the box. It should provide the methods for capturing:

Planned value

Actual cost

Percent complete – progress

With those 3 values captured at an activity level, the system will gain a full three-dimensional picture of each activity, the WBS rollup, and the project as a whole.

Key EVM Capabilities Your Software Should Have:

- Three-dimensional performance tracking – Monitor Planned Value (PV), Earned Value (EV), and Actual Cost (AC) in conjunction to get a complete picture of project status.

- Predictive performance indices – Calculate Cost Performance Index (CPI) and Schedule Performance Index (SPI) to predict end outcomes based on current trends.

- At-a-glance variance analysis – Instantly identify cost variances (CV) and schedule variances (SV) to see in which direction the project is drifting.

- Estimate at Completion (EAC) projections – Predict final project costs using multiple forecasting methods based on current performance.

- Visual performance dashboards – Present complicated EVM metrics in simple-to-interpret charts that stakeholders can easily understand.

This integrated approach eliminates blind spots from tracking schedule and budget separately, giving you early warning systems that are essential to proactive project controls.

5. Change Order Management Tools

Change orders are inevitable in construction, but poor change management tools and processes can compromise project success, profitability and client trust. A lack of process and the right tools to capture, budget, approve and execute on change orders can significantly compromise the success of a project. It can also lead to legal disputes and substantial financial risk. Your project controls system should provide tools to elegantly accept and apply scope changes into the budget, schedule and resourcing. Change orders can be very disruptive if not handled well. As I’m sure you know, it’s worth the effort to manage them carefully and forecast their impacts.

Essential Change Order Management Capabilities:

- Centralized change request tracking – Capture and document every change order from initiation through final approval

- Automated impact analysis – Calculate effects on budget, schedule, and resources instantly when changes are proposed

- Configurable approval workflows – Route requests through appropriate stakeholders based on value thresholds and project roles

- Cost and schedule baseline comparison – Show exactly how each change affects original plans versus current forecasts

- Audit trail documentation – Maintain complete records of who requested what, when, and why for dispute resolution

- Client visibility portals – Give owners real-time access to change status, preventing surprises and disputes

This structured approach protects margins while maintaining the transparency that strengthens

Learn More About Change Order Management

Making The Right Choice

The right project controls software isn’t just a management tool; it’s a strategic differentiator that separates successful project outcomes from those that suffer setbacks, overruns and delays. These essential capabilities deliver predictive intelligence that,

- Spot problems long before the Impact deadlines or budgets

- Provide financial protection through real-time cost visibility

- Promote operational efficiency by eliminating duplicate data entry,

- Deliver competitive positioning that lets you respond faster than rivals using outdated tools.

Any system that you evaluate for centralized project management and project controls lacks these features, you would be operating with unnecessary risk. Modern integrated platforms consolidate these capabilities into unified solutions that give teams the visibility, control, and the kind of agility today’s projects demand. The question isn’t whether to invest in robust project controls—it’s rather whether you can afford not to.

Learn More

Want to see how 4castplus helps teams measure real progress on the jobsite? By capturing production quantities alongside labor, equipment, and cost, 4castplus connects daily field activity directly to planned work and budgets. Gain objective visibility into progress, productivity, and performance, identify issues early, and keep projects on track with data-backed insights, not assumptions.

Platform

Platform Solutions

Solutions Owners

Owners Contractors

Contractors Engineering/EPCM

Engineering/EPCM Professional Services

Professional Services Resources

Resources White Papers

White Papers Case Studies

Case Studies Blog

Blog Videos

Videos Frequently Asked Questions

Frequently Asked Questions Company

Company About

About