Read In 10 Minutes

Part 1: Setting Up The Project Plan For Forecasting

To properly prepare for effective forecasting during project execution, the project planning stage is vital. The nominal extra effort that goes into planning will make things run smoothly and far more streamlined while the project is underway. Shifting more effort to the planning stage has a sizable payoff, as projects are often overly resourced for an execution phase that could be simplified with better planning. This leads to lower overall operational costs for the management of major projects.

Planning For Forecasting

There are of course many essential elements that go into a good project plan, however for the purposes of this article, we’ll zero-in on a few of those key elements required to achieve good forecasting ability down the road during project execution. It’s at the planning stage that the project needs to be setup so that it can be first measured, then forecasted, then reported on. We therefore need the necessary structure in place to streamline the process of iteratively measuring current progress & performance, so that the remainder can be forecasted from there.

This Includes The Following:

- A well-designed Work Breakdown Structure

- A time-phased budget

- Well-defined progressing methods

- Automated and distributed progress measurements

- Determine what and how you’ll forecast

Learn More About Construction Forecasting

A Well-Designed Work Breakdown Structure & Cost Breakdown Structure

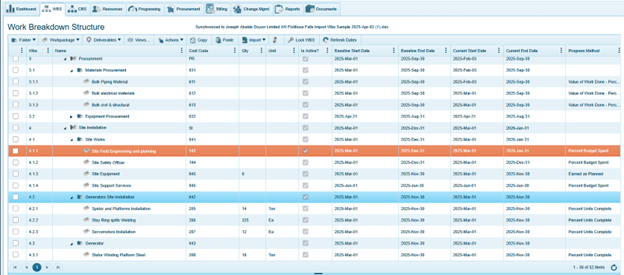

Best practices in WBS design are beyond the scope of this paper; it is worth mentioning that the WBS needs to be defined down to the activity level, where activities are designed to be measurable in terms of budget, cost, and physical progress. You may refer to Activities as Tasks or Work packages, but in any case, they represent the lowest level of the WBS, and it’s from there that the project is budgeted, tracked, progressed, and reported on. This is important, as these elements need to converge at the activity so that they can be compared against each other. The screenshot below shows a section out of a work breakdown structure showing the activity at the lowest level, and how they roll up to each level above that in the hierarchy.

Notice also in the WBS in the screenshot above, that for many of the activities there is a progress quantity (plus rate) attached to the activity. For example, 4.2.2 has a progress amount of 325 Each. These quantity-plus-rate properties represent the budgeted Production Quantities for those activities that can be physically measured in that way. As we’ll see further below in the project execution section, using progress quantities like this can be instrumental in producing accurate progress measurements.

A Time-Phased, Resource-Level Budget

The project budget needs to be merged with the schedule – along with any time-phased overrides – so that critical metrics like Planned-Value and SPI can be calculated, and so that timeline curves can be used to visualize the project spend forecast. Time-phasing is essential for cash flow planning, as you can see the 4castplus screenshot below, where the budget curve compares against the actual cost and forecast curves over a timeline. Ideally, you should be time-phasing your project budget as well as your committed costs, especially if a significant portion of your project is subcontracted out. Each subcontract or purchase order can have its own unique cash flow plan for milestone payments, delivery dates, etc. This will provide a more accurate spend curve for both the budget and the forecast.

By time-phasing the budget and the forecast, you’ll be able to produce the month-over-month financial forecast that all project stakeholders crave.

A Budget Derived From Resource-Level Estimating

To perform detailed forecasting, a detailed budget is required. This identifies the labor & equipment hours, material quantities, etc. that go into the budget. When performing a forecast, the team can then compare the budgeted against the burned-to-date and enter the forecasted remaining amounts. By forecasting remaining resources, you’re essentially recalibrating the project budget on regular increments as new information is learned. We’ll see how these factors fit into the forecast further below in the project execution section.

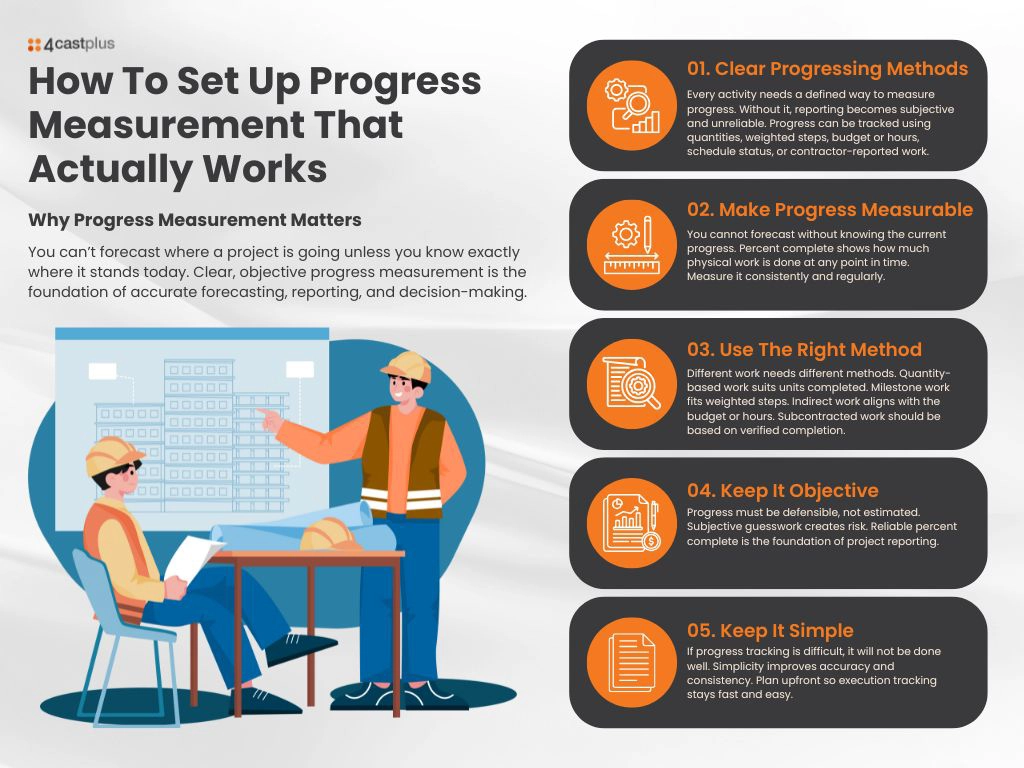

Well-Defined Progressing Methods

Each project activity that will be budgeted and tracked should have a defined method for how it will be progressed, along with a structured method for reporting that progress. This could be based on, for example: Rules of Credit, Weighted Steps, Production Quantities, Budget, Schedule, etc. Upfront planning around physical project progress is likely the most undervalued aspect of project planning, unless you’re a contractor billing your client on progress claims.

Set It Up So That It’s Easy To Measure

Like everything in life, you need to know where you’re at before you can predict where you’re going. Measuring project progress therefore, is the starting point for forecasting. By measuring progress, you’re essentially calculating how far along the project has come – in terms of physical progress – at any given time during its execution. This is typically represented as percent complete, and should be measured incrementally at regular intervals over the life of the project.

The setup for measurement effectively boils down to defining how each activity in the WBS is going to be progressed. Not all activities are wired the same, so you’ll need to apply the method of progressing that suits each activity. Here are some progressing methods to consider:

- Percent Units Completed. This is useful for longer, more complex activities that can be quantified through a quantity of installed or completed units.

- Rules of Credit or Weighted Steps. This is valuable for activities that warrant being split up into weighted sub-deliverables that are progressed (or completed).

- Percent Budget or Percent Hours Spent. For activities that are difficult to quantify in terms of installed quantities, such as labor indirects.

- Schedule-based. For smaller activities that can be automatically marked as a certain percentage complete based on the underlying schedule.

- Contractor Based (VOWD). This is for activities that are dependent on the successful completion of work done by subcontractors.

That’s by no means an exhaustive list of options, but it represents the most common methods, and shows that successful progress measurements need to be objective. Subjective guesswork should be avoided in the calculation of percent complete, as a progress measurement needs to be defensible. It is the most essential building block for all project status reporting.

It also has to be straightforward and not introduce a lot of extra work. This is important because if it’s difficult or time-consuming, people just won’t do it. Making it easy to do doesn’t have to compromise the accuracy of the results; it can, in fact, improve the legitimacy of the measurement as it removes much of the subjectivity that can cloud accuracy. To accomplish that, you’ll shift the bulk of effort to the upstream planning stage so that the practice of capturing and measuring during execution becomes simplified – automated in many cases – and carried out with minimal effort.

Automated & Distributed Progress Measurements

Accurately measuring project progress is arguably the most challenging component of project planning and execution. Again, a little extra upfront planning can really simplify the measurement process. It’s key that capturing progress is both distributed and automated wherever possible. This is vital for two reasons:

- It shares the effort and responsibility to the wider project team – and aligns it with the natural execution of the project. This reduces the reliance on a small group of individuals.

- By distributing and automating, it ensures that progress measurements will be performed objectively, will not be overlooked and the results will be based on rigorous and transparent methods

Determine What & How You’ll Forecast

A progress measurement is clearly a valuable snapshot in time. However, it only provides indicators of past performance and current state. These indicators can of course then be used to predict future outcomes if productivity (CPI) continues as it was. But what if past performance is a misleading indicator of where the project is going? For example, maybe you just came out of a cold winter that slowed things down, and now you need to predict the future based on a more optimistic productivity factor. Standard EVM calculations for predictive values such as ETC and EAC use past performance to forecast the future state. While this is good information, it doesn’t consider any factors that may influence the future.

For another example, let’s say that half-way through your project your construction manager tells you that updated drawings are indicating that the amount of steel beams required to complete a particular activity was underestimated in the initial budget. He’s predicting they’ll likely need an extra 250 over and above what they have. So, as a project controller, how do you reflect that in your project reports? It’s too soon to open a change order as there’s not enough information yet, but you nevertheless need to raise awareness of it as soon as possible.

This is where the forecast comes in. It acts as the early identification of trends and changes that may or may not play out as the project is completed. This example could be one of several that could be part of an overall project forecast; and each situation can be forecasted in a few ways:

- By overriding the estimate-to-complete (ETC) on activities

- Overriding the cost-performance-index (CPI) on activities

- Or, as in our steel beam example, inputting resource-level quantity forecasts of remaining work, materials, equipment, hours, etc.

By planning what and how you’ll forecast, you’re arming yourself with the upfront tools and methods for your forecasting process.

Learn More

Want to see how 4castplus turns timesheet data into real project insight? By capturing labor hours directly from the jobsite and linking them in real time to cost codes, budgets, and progress, 4castplus gives teams immediate visibility into labor cost, productivity, and project performance. Identify issues earlier, reduce manual handoffs, and use the hours you’re already collecting to protect margins and keep projects on track.

Platform

Platform Solutions

Solutions Owners

Owners Contractors

Contractors Engineering/EPCM

Engineering/EPCM Professional Services

Professional Services Resources

Resources White Papers

White Papers Case Studies

Case Studies Blog

Blog Videos

Videos Frequently Asked Questions

Frequently Asked Questions Company

Company About

About