Read In 14 Minutes

Measure Progress, Protect Profits

Construction projects often operate on tight margins. Inaccurate progress data can make it appear that a project is on track when, in reality, costs are spiraling. It is essential for any project, that there are accurate progress measurements in place.

Precise progress measurement enables timely decisions, protects margins, and maintains control over project costs . It forms the foundation for reliable forecasting and earned value analysis, the metrics that separate proactive management from reactive crisis response.

This article examines why accurate progress measurement is crucial, how it supports predictive project controls, and the proven practices that enable reliable measurements.

The High Stakes of Progress Measurement in Construction

Progress measurement in construction isn’t just a reporting exercise; it’s a financial and operational imperative.

Whether you’re building a bridge, an industrial facility, or a high-rise, progress data drives almost every key management decision:

- Revenue recognition – Determine billable amounts based on verified completion

- Schedule performance – Identify delays before they cascade into major problems

- Earned value validation – Confirm you’re generating the expected value for costs incurred

- Productivity assessment – Evaluate crew and subcontractor efficiency objectively

- Cost forecasting – Project final costs based on actual completion rates

If your progress data is unreliable or inconsistent, every downstream calculation, from EVM to forecasts to revenue recognition, is built on shaky ground. Inaccurate progress reporting can distort project visibility, lead to billing disputes, and mask early warning signs of overruns.

On the other hand, accurate and timely progress measurement delivers real-time project clarity, enabling teams to correct courses quickly and protect margins before small issues become financial crises.

The Backbone of Performance Tracking

At its core, progress measurement answers one simple question: “How much work has been accomplished?”

But in construction, “work accomplished” can mean very different things depending on the scope, discipline, and contractual structure. That’s why defining how you measure progress is just as important as measuring it.

Common Progress Measurement Methods

- Units Completed – Ideal for repetitive, quantifiable activities (e.g., cubic meters of concrete poured, welds completed). Progress is based on physical quantities achieved versus total planned quantities.

- Hours Burned – Best for labor-intensive work where effort, not units, defines progress. The ratio of hours spent versus total planned hours indicates the percentage complete.

- Rules of Credit – Suited for complex activities broken into milestones or sub-steps, each assigned a weighted credit (e.g., engineering deliverables, design packages).

- Schedule, Based Progress – Aligns progress to schedule milestones or planned durations. Often used in conjunction with earned value reporting.

- Value of Work Done (VOWD) – Used on major capital projects to measure progress financially, tying percent complete to committed and spent costs.

Each method has its advantages, but the key is consistency. A disciplined approach ensures that everyone, from project controls to finance to field teams, interprets progress in the same way.

Learn More About Progress Measurements

Why Accuracy Matters

Accurate progress measurement affects far more than just status updates. It underpins almost every core business process in construction project management.

1. Improved Forecasting and Cost Control

Accurate forecasting depends on knowing how much work is complete and how efficiently it was executed. Flawed progress data corrupts cost-to-complete calculations, creating either false confidence or unwarranted alarm.

Reliable progress measurement enables precise forecasting, reveals cost trends early, and supports data-driven adjustments that protect budgets before overruns materialize.

2. Timely Revenue Recognition

For contractors working on fixed-price or long-term contracts, revenue recognition depends on verified progress. Accounting teams use progress percentages to determine how much revenue can be recognized each period.

Inaccurate progress data, whether lagging or overstated, creates accounting misstatements, delays invoicing, and triggers client disputes over billing accuracy.

3. Earned Value Management (EVM) Integration

Progress measurement is the foundation of Earned Value Management, the industry’s standard for performance tracking. The earned value of an activity equals its budgeted cost multiplied by its percent complete.

Without credible progress data, EVM metrics like Cost Performance Index (CPI) and Schedule Performance Index (SPI) are meaningless. When done right, however, progress measurement transforms EVM from a theoretical exercise into a real-time performance dashboard.

4. Crew Productivity & Operational Insight

At the field level, progress tracking helps supervisors evaluate crew performance, identify productivity bottlenecks, and optimize resource allocation.

By comparing planned versus actual output, teams can pinpoint inefficiencies, whether caused by labor issues, supply chain delays, or unforeseen conditions, and take corrective action before it impacts the schedule.

5. Client Confidence & Transparency

Clients want visibility. When you can present progress data that’s traceable, verified, and backed by quantitative metrics, you build trust. It shows professionalism, strengthens relationships, and reduces disputes over billing or scope.

The Cost of Inaccurate or Inconsistent Progress Data

When progress measurement is inconsistent, perhaps tracked manually, delayed, or based on subjective estimates, the ripple effects are wide-reaching:

- Forecasting errors: Misstated progress distorts future cost and completion predictions.

- Cash flow challenges: Late or inflated progress affects billing and cash management.

- EVM distortion: Performance indices lose meaning without reliable inputs.

- Decision delays: Management lacks confidence in data, slowing corrective action.

- Loss of credibility: Clients and stakeholders question project reporting integrity.

In short, unreliable progress measurement can quietly erode profitability, often without teams realizing it until too late.

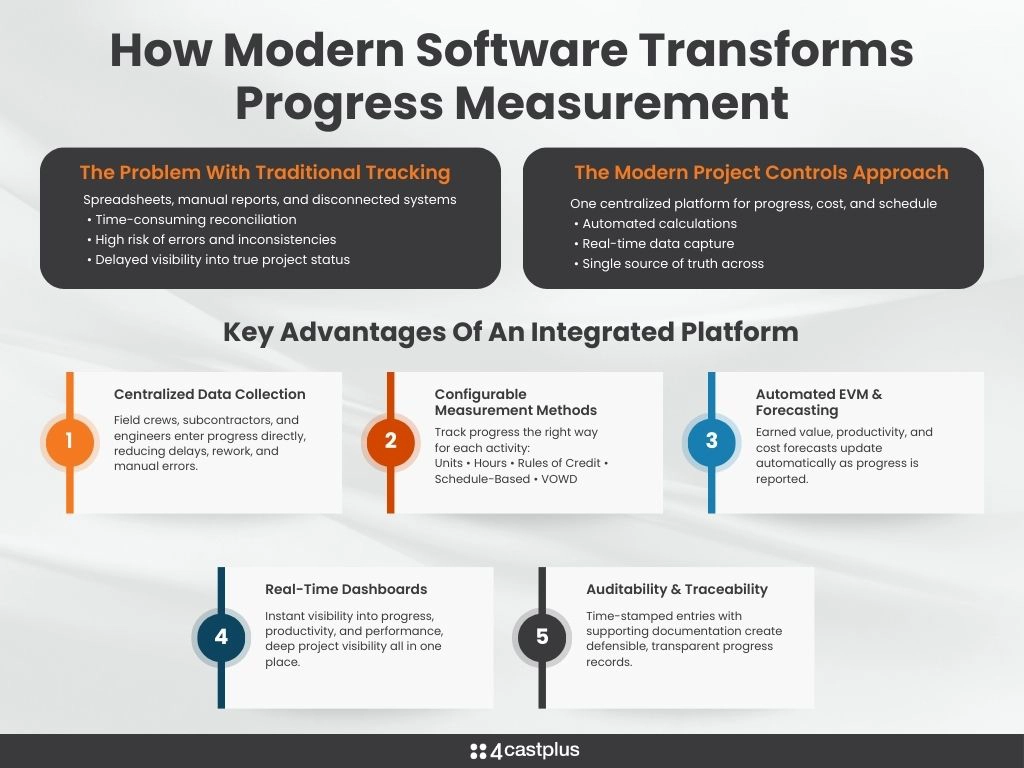

How Modern Software Transforms Progress Measurement

Traditional progress tracking methods, spreadsheets, manual reports, and disjointed systems are error-prone and time-consuming. They require constant reconciliation between field data, cost systems, and schedules.

Modern project controls software like 4castplus centralizes all of that into one cohesive environment, automating calculations, ensuring traceability, and enabling real-time visibility into progress across activities, disciplines, and contractors.

Key Advantages Of An Integrated Platform

- Centralized Data Collection

Field teams, subcontractors, and engineers input progress directly into the system, reducing data lag and manual entry errors. - Configurable Measurement Methods

Each activity can be assigned the method best suited to its work type (units, hours, rules of credit, etc.), ensuring flexibility and consistency. - Automated EVM and Forecast Updates

As progress is entered, earned value, cost performance, and forecasts update automatically, eliminating duplication and human error. - Real-Time Dashboards

Visual dashboards present project health indicators instantly , giving managers deep project visibility all in one place. - Auditability and Traceability

Every data point is time-stamped and linked to source documentation, supporting internal reviews and client transparency.

With this kind of automation, progress measurement becomes less about chasing data and more about interpreting insights, empowering teams to act proactively rather than reactively.

Scaling Progress Measurement Across Large Projects

On smaller projects, tracking progress might involve a handful of activities and can be managed manually. But large-scale capital projects often have thousands of activities across multiple contractors, disciplines, and locations.

At that scale, progress measurement becomes a logistical challenge:

- Multiple measurement methods in use simultaneously.

- Different stakeholders report at different frequencies.

- Data coming from varied sources, field reports, time sheets, and vendor updates.

Managing this complexity requires standardized processes and technology that can handle high volumes of data without losing accuracy.

4castplus, for instance, enables teams to establish a unified measurement framework that integrates with project schedules, cost codes, and procurement data, ensuring that no matter how large the project, progress remains measurable, consistent, and actionable.

Best Practices for Implementing Reliable Progress Measurement

To get the most out of progress measurement, organizations should establish clear practices that promote accuracy, consistency, and collaboration.

1. Define Clear Measurement Methods Early

Establish the rules of measurement during project setup. Each work package or activity should have a defined method suited to its nature, and everyone involved should understand how it’s applied.

2. Maintain Consistent Frequency

Measure progress at regular intervals, weekly or biweekly, to keep data fresh and actionable. Sporadic updates limit the ability to trend performance or detect early deviations.

3. Link Progress to Both Cost & Schedule

Integrating progress with both cost and schedule systems provides a complete picture of performance. This alignment allows teams to track time, cost, and output in unison.

4. Leverage Field Data Capture Tools

Empower field teams with mobile tools to input progress data directly from the site, minimizing reporting lag and transcription errors.

5. Validate & Audit Regularly

Implement spot checks or validation reviews to ensure reported progress matches actual physical work.

6. Automate Calculations and Reporting

Use integrated software to automate earned value and forecasting updates, freeing project controls teams from manual data manipulation.

7. Train & Communicate

Ensure all stakeholders, from field supervisors to finance, understand the purpose and process of progress measurement. Alignment drives better data quality.

Turning Progress Data Into Action

Accurate progress measurement is powerful, but only if it’s used effectively. The real value comes when organizations translate data into decisions.

Project managers can use trending progress reports to:

- Identify declining productivity early.

- Adjust resource allocation before delays escalate.

- Forecast completion dates and costs more accurately.

- Justify change orders with objective data.

When progress data is accessible, real-time, and trustworthy, it empowers teams to make quick decisions and take corrective action, keeping projects profitable and on course.

Learn More About Construction Data

The Strategic Value of Progress Measurement

Beyond the operational benefits, strong progress measurement practices deliver strategic advantages:

- Benchmarking and Continuous Improvement: Historical data helps establish productivity benchmarks and refine future estimates.

- Risk Mitigation: Early detection of slippage reduces risk exposure.

- Stakeholder Confidence: Transparent reporting enhances trust with clients, partners, and investors.

- Scalability: A standardized framework supports organizational growth across multiple projects.

In essence, progress measurement transforms project controls from a reactive reporting function into a strategic performance management system.

Measure Better, Build Smarter

Progress measurement may seem like a technical detail, but in reality, it’s the heartbeat of every successful construction project. Without it, forecasting falters, costs drift, and profits shrink.

When teams commit to accurate, consistent, and automated progress tracking, they gain something far more valuable than data: clarity, confidence, and control.

Whether you manage small projects or massive industrial programs, investing in reliable progress measurement processes, supported by an integrated platform like 4castplus, is one of the smartest ways to ensure profitability, accountability, and long-term success.

Learn More

Want to see how 4castplus strengthens project controls through accurate progress measurement? By capturing verified progress alongside labor, cost, and schedule data, 4castplus gives teams real-time visibility into earned value, productivity, and forecasted outcomes, helping you identify risk early, protect margins, and keep projects on track with confidence.

Platform

Platform Solutions

Solutions Owners

Owners Contractors

Contractors Engineering/EPCM

Engineering/EPCM Professional Services

Professional Services Resources

Resources White Papers

White Papers Case Studies

Case Studies Blog

Blog Videos

Videos Frequently Asked Questions

Frequently Asked Questions Company

Company About

About